Making round maize silage bales is an effective way to improve forage preservation and livestock nutrition. Below is a step-by-step procedure for making corn silage round bales using our silage baling and wrapping machine.

Preparation

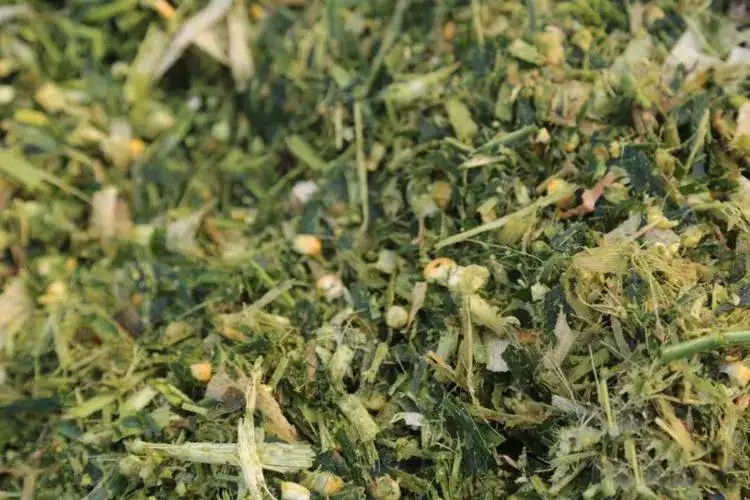

Before you start making maize silage bales, you need to prepare the right amount of corn stover and the right equipment. Corn stalks should be harvested at optimum maturity to ensure nutrient enrichment. After harvesting, the corn stalks need to be properly cut to the right length for subsequent baling operations.

During this step, you can use silage harvester for maize harvesting and crushing, or use the chaff cutter to shred them into proper pieces.

Corn silage bundling

Our silage baler wrapper is efficient equipment designed specifically for silage.

First, collect the cut corn stalks and put them near the machine, then start the silage round baler and put the stalks into the machine. The machine will automatically convey silage into the bundling silo, then compress and bale it into round bales.

Silage bale wrapping

After baling, the round maize silage bales will come to the wrapping section. The use of forage film is crucial in the baling and wrapping process.

Our silage wrapper machine automatically performs the wrapping operation to ensure that each bale is tightly wrapped. This not only prevents the entry of air, but also prevents moisture loss, keeping the silage fresh and nutritious.

Storing maize silage bales

Once forage baling and wrapping are completed, silage round bales need to be stored in a dry, cool place, out of direct sunlight and rain.

Generally, silage needs to be fermented for 3-6 weeks to achieve optimum feed quality. During this time, the integrity of the bale wrap needs to be checked regularly to ensure there are no air leaks.

Summary

We hope this article has helped you better understand how to make round corn silage bales with our baling and wrapping machines. If you have any questions or need further assistance, please feel free to contact us.