Introduction of Baler and Wrapper Machine

The bundling and wrapper machine can bundle crushed silage raw materials with high-density compaction. And then wrap them with a stretched film to create an anaerobic fermentation environment. Finally, complete the lactic acid fermentation process. This silage method has been widely recognized and used by developed countries in Europe, the United States, and Japan.

The fully automatic silage bundling film machine is a new generation of fixed-type baler and wrapper machines. The silage feeds enter the silage bundling film machine by its conveyor automatically. The corn stalks and straws are automatically fed through the conveyor belt, which greatly saves labor. The bundling and wrapper machine is low-cost and high-efficiency.

The working efficiency of the baler and wrapper machine is extremely high. It can complete the bundling of 20-30 grass bales or 30-40 corn bales per hour. A single bale of grass can reach 350-550kg, a single corn bale can reach 500-700kg, and the bale density is high.

Materials Suitable for Silage Baler and Wrapper Machine

It can silage corn stalks, sugarcane leaves, grasses, sweet potato vines, reeds, and bean straws. After adding water and bacteria packing, dry straw can micro-stored.

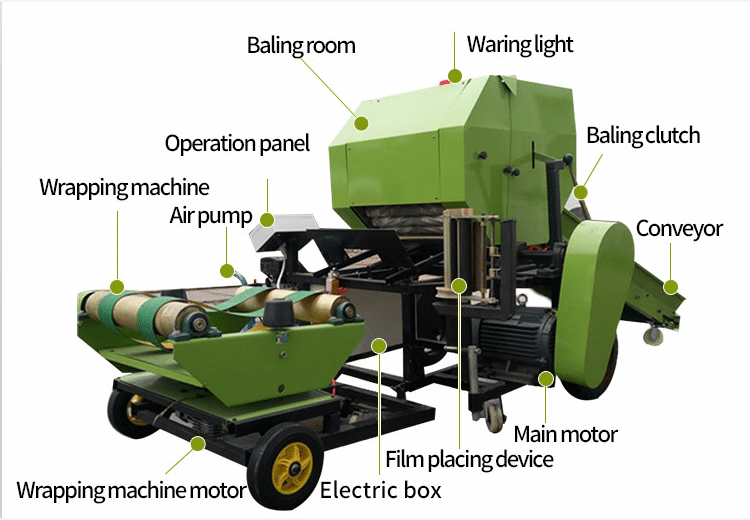

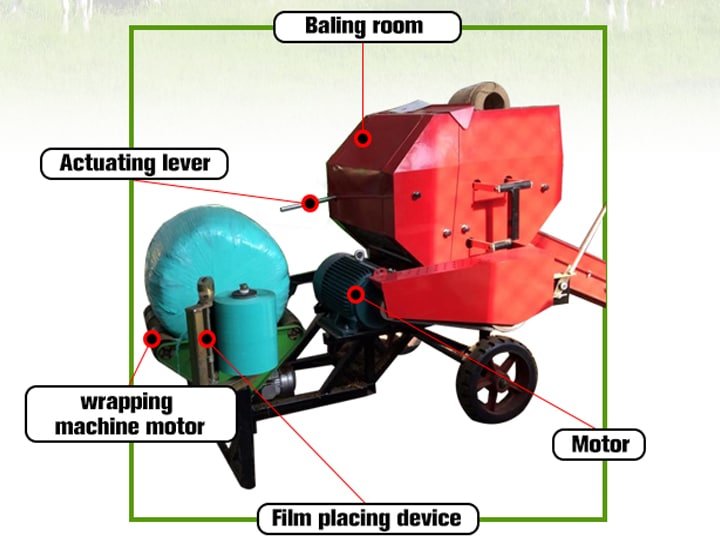

Structure of Silage Bundling and Wrapper Machine

The Benefits of Bundling and Wrapping

- The wrapped silage has less material loss, which can be stored for a long time. The silage made by the silage bundling film machine has a soft texture, sweet and sour fragrance, good palatability, high digestibility, and less loss of nutrients. The whole production of baler and wrapper machine is not restricted by time and location. Also, it is not restricted by the storage location. If processing is carried out indoors, it is not restricted by the weather.

- Compared with other silage methods, the process of silage bundling and wrapper machine has good sealing properties. And fewer nutrients are lost through juice, which has no secondary fermentation. The transportation and use are more convenient, which is conducive to the commercialization of forage. This is of great significance for promoting the industrialization of silage processing.

How to Use the Baled Silage?

Under normal circumstances, the silage made by the bundling and wrapper machine can complete the fermentation process after 20-30 days of sealing. At the same time, you can also use it. The quality of silage is good or bad, and whether it can be used for feeding can be judged from smell, color, and touch. Generally, good quality silage has a sour fragrance, greenish-green or yellow-green, and it feels loose in the hand, soft and slightly moist. Note when feeding:

- When taking the silage, start from the corner and go from top to bottom. The amount taken each time should meet the daily feed intake. Take as much as you need so as to ensure the freshness of the silage, and still pay attention to sealing after taking it.

- If livestock doesn’t like to eat when they start feeding silage, so they should be trained. You can let the livestock be hungry for a meal or two before feeding the silage. You can also sprinkle some fodder that the livestock prefers to eat on the silage so that the livestock will gradually adapt to its smell.

- The feeding amount should be increased gradually from less to more. Generally, each cow eats 20 kg per day and sheep 3-5 kg per day.

- Don’t feed silage alone, you can feed it with pasture or with other hay.

- If the silage freezes in winter, you should melt before feeding.